It is recommended that a seven (7)-point preventative cooling system maintenance check be performed at least once every two years. Consult your vehicle owner’s manual for specific auto guidelines. This inspection is designed to identify areas that need attention, and consists of:

- a visual inspection of all cooling system components, including belts and hoses

- a radiator cap pressure test to check for the recommended system pressure level

- a thermostat check for proper opening and closing

- a pressure test to identify any external leaks to the cooling system parts; including the radiator, water pump, engine coolant passages, radiator and heater hoses and heater core

- an internal leak test to check for combustion gas leakage into the cooling system

- an engine cooling fan test for proper operation

Cooling System Operation

Antifreeze/Coolant

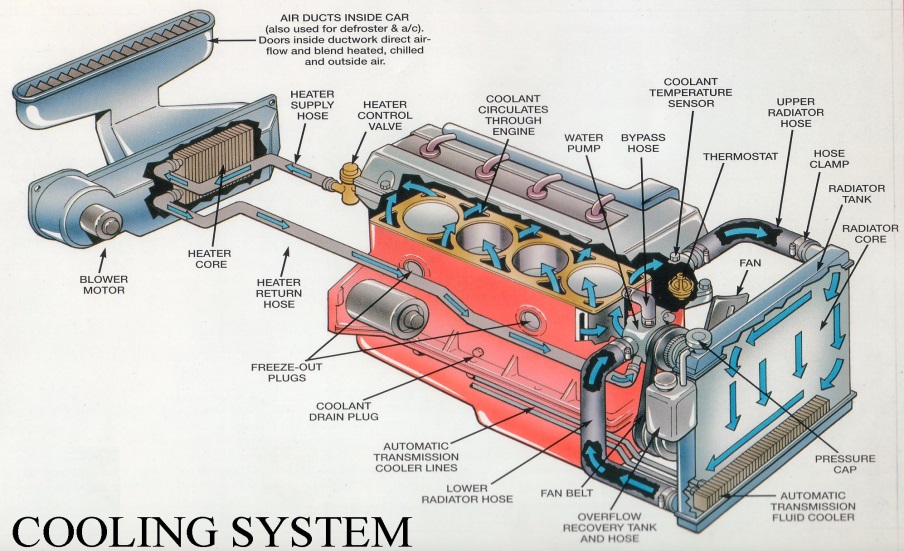

The main function of the Cooling System is to carry heat away from the engine and maintain the desired operating temperature. This is accomplished by circulating antifreeze/coolant through the engine, where heat is generated, and carrying it to the radiator to be cooled.

Modern automobiles operate in a wide variety of ambient temperatures, from well below freezing to well over 100 F. The fluid used to cool the engine must have a very low freezing point, a high boiling point, and it must have the ability to transfer heat.

An adequate amount of an antifreeze/coolant and water mixture is necessary to reduce the possibility of engine overheating and freezing, and contain additives to prevent rust and corrosion in the cooling system.

Water is one of the most effective fluids for holding heat, but water freezes at too high a temperature to be used in automobile engines alone.

The fluid used in most vehicles is a mixture of water and ethylene glycol, also known as “antifreeze” or “coolant”. By adding antifreeze to water, the boiling and freezing points are improved significantly.

The temperature of the coolant can sometimes reach 250 to 275 F (121 to 135 C). Even with antifreeze added, these temperatures would boil the coolant. To prevent this, the cooling system is pressurized, which further raises the boiling point of the coolant. Most systems have around 14 to 15 pounds per square inch (psi), which raises the boiling point approximately 45 F so the coolant can endure the high temperatures produced in the engine.

Coolant Hoses

The radiator hoses and heater hoses are easily inspected by opening the hood and looking. You want to be sure that the hoses have no cracking or splitting and that there is no bulging or swelling at the ends.

If there are any signs of problems, the hose should be replaced with the correct part number for the year, make, model and engine of the vehicle.

Never use a universal hose unless it is an emergency and a proper molded hose is not available.

For either the radiator hoses or the heater hoses, make sure that you route the replacement hose in the same way that the original hose was running. Position the hose away from any obstruction that can possibly damage it and always use new hose clamps.

After the cooling system is refilled with the proper coolant mixture, a pressure test should be performed to ensure that there are no leaks.

Belts

On most older vehicles, the water pump is driven by either a V belt or serpentine belt on the front of the engine that is also responsible for driving the alternator, power steering pump and air conditioner compressor. These types of belts are easy to inspect and replace if they are worn. Check for dry cracking on the inside surface of the belt.

On newer vehicles, the water pump is often driven by the timing belt. This belt usually has a specific life expectancy at which time it must be replaced to insure that it does not fail. Since the timing belt is inside the engine and will require partial engine disassembly to inspect, it is very important to replace the timing belt at the scheduled interval.

Things to watch for

- Check antifreeze/coolant level monthly. Only use a 50/50 solution of anti-freeze/coolant and water.

- Water quality plays an important role in protecting the cooling system. A high mineral content may cause scaling or corrosion. Deionized or distilled water should be used in 50/50 solution

- CAUTION: Do not remove the radiator pressure cap when the engine is HOT.

- Inspect belts monthly. Replace belts that are worn, frayed or glazed. Adjust belts when more than 1/2 inch can be depressed between the pulleys.

- Belts with spring-loaded tensioners do not require manual adjustments.

- Replace bulging, rotten, or brittle hoses and tighten hose clamps. If a hose looks bad or feels too soft or too hard, it should be replaced.

Leave a Reply