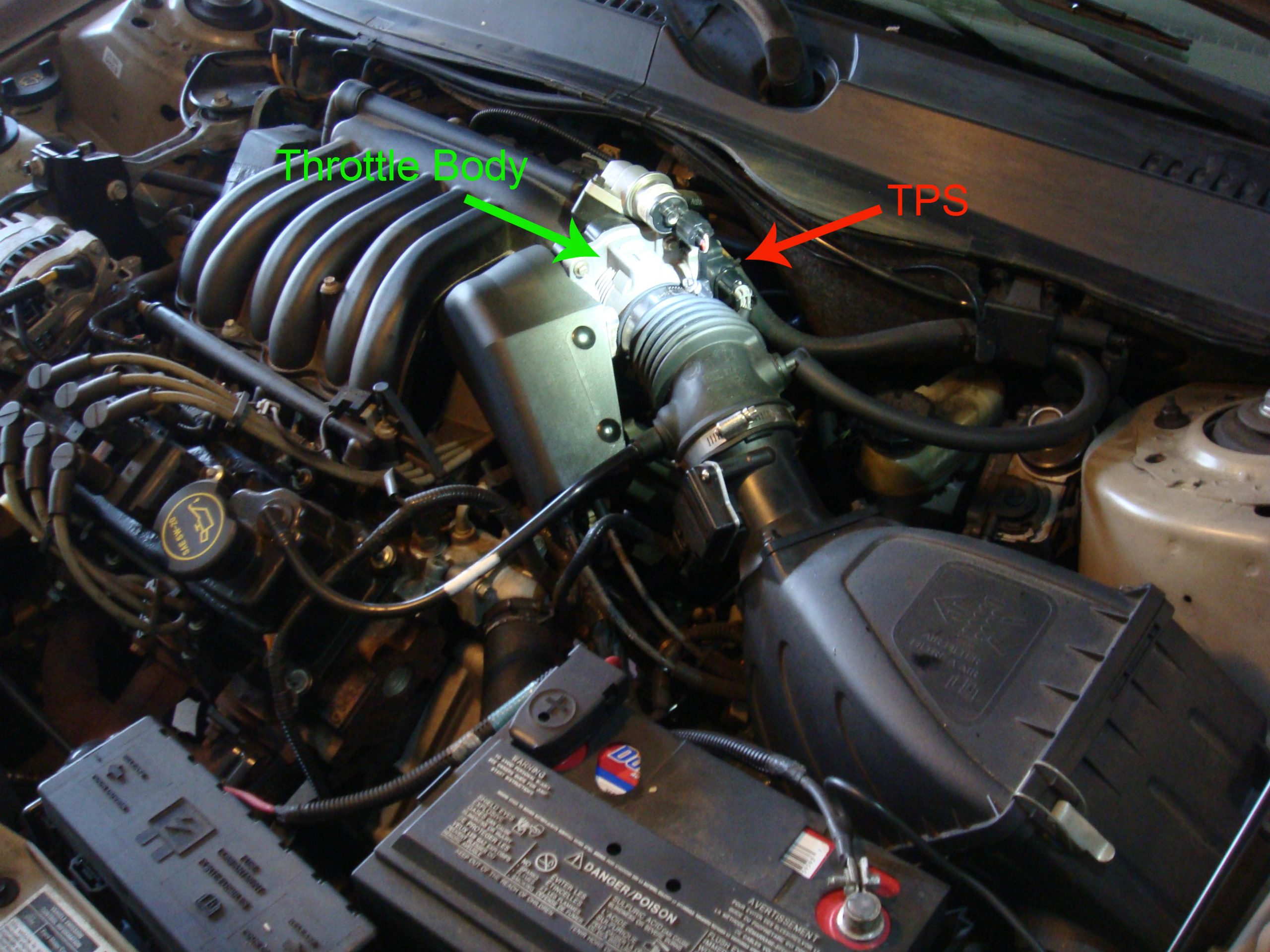

The throttle position sensor is commonly used in modern fuel-injected engines. Usually located in the butterfly spindle attached to the body of engine, the throttle position sensor is very useful in monitoring the position of the valve in your engine.

As the name implies the throttle position sensor tells the engine computer where the throttle blade is. Your engine needs to know precisely this position to help achieve better performance. This device determines the exact position of your car’s throttle and relays the information to the engine control unit or ECU in the form of sensor signals (The sensor works around certain parameters and when these parameters are met or are not met, the sensor sends the corresponding signals to the engine control unit). These signals are increasing or decreasing voltages that are produced depending on how much power is required by the driver from the engine. For example, as you depress the throttle the throttle position sensor tells the engine computer that you are accelerating and coupled with other sensors how much fuel to deliver through the fuel injectors. If you let off the accelerator the throttle position sensor tells the engine computer to return to idle speed, and the engine computer reduces fuel flow accordingly. Without this kind of sensor, the engine computer will figure it out via other sensors but response will be slower.

There are a number of throttle position sensors available in the market today, among which the switch type and the potentiometer type are the two most common ones. The switch type throttle position sensor cycles on when there is electrical continuity in the system and off when the electrical flow in the system is interrupted. The potentiometer type works by gradually increasing the power supply to the computer and sending constant signals to it. It has pre-programmed parameters which you cannot alter.

At heart, a throttle position sensor is effectively a potentiometer with three connections-voltage reference, signal and ground. Generally speaking, a potentiometer is a variable resistor connected to a dial, and it provides a voltage value based on the position of the dial. Voltage reference refers to the signal range that your car computer needs to know to make a decision. It is typically 5 volts. The voltage signal a sensor sends varies from 0 volts to 5 volts. These two numbers are the minimum and the maximum respectively. Voltage signal always takes the short-cut path of least resistance to flow. The more the resistance in the path of electricity, the more voltage is consumed, and therefore voltage is less. The ground source is necessary to complete the path for the electrical current to flow.

Since throttle position sensor does a lot for your vehicle, it is made from premium materials to keep it from breaking down quickly. However, eventually your throttle position sensor will wear out and therefore lose its ability to send proper signals to the ECU. So when this happens, get a replacement right away.

The critical role a throttle position sensor plays in a high performance engine

by

Tags: