Modern cars apply brakes on all four wheels. Since front brakes play a greater part in stopping the car than the rear ones, many cars have disc brakes, which are generally more efficient, at the front and drum brakes at the rear. They are all operated by a hydraulic system.

What is an auto braking system?

An automotive braking system is a group of mechanical, electronic and hydraulically activated components which use friction / heat to stop a moving vehicle.

How does a braking system work?

When the brake pedal is depressed, the pressure on the brake pedal moves a piston in the master cylinder, forcing the brake fluid from the master cylinder through the brake lines and flexible hoses to the calipers and wheel cylinders. The force applied to the brake pedal produces a proportional force on each of the pistons.

The calipers and wheel cylinders contain pistons, which are connected to a disc brake pad or brake shoe. Each output piston pushes the attached friction material against the surface of the rotor or wall of the brake drum, thus slowing down the rotation of the wheel.

When pressure on the pedal is released, the pads and shoes return to their released positions. This action forces the brake fluid back through the flexible hose and tubing to the master cylinder.

What components are in the auto braking system?

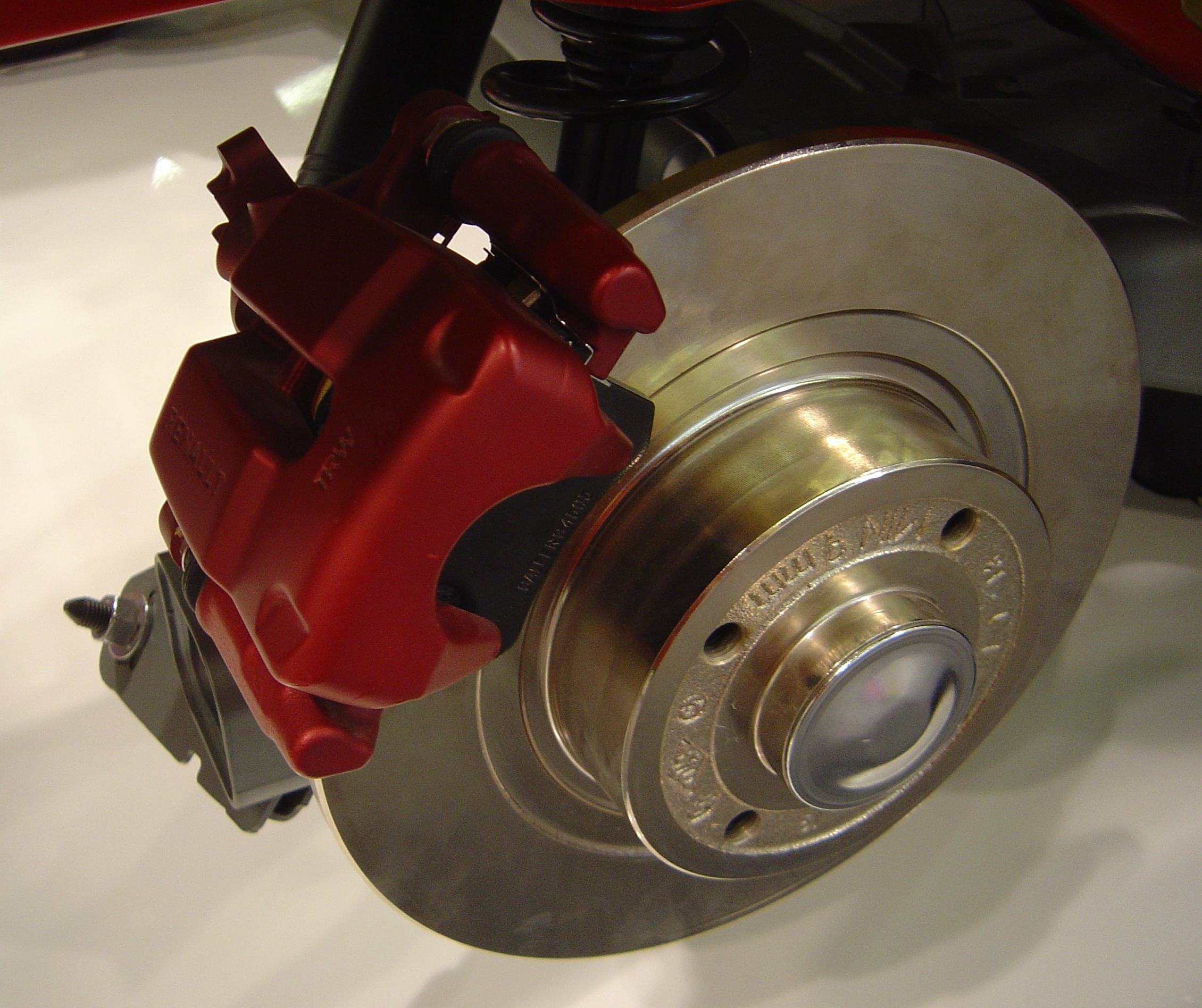

Disc Brakes

Disc Brakes are comprised of a disc or rotor, a caliper assembly, disc brake pads and the wheel bearings and hardware necessary to mount the components on the vehicle. The caliper is connected to the master cylinder through tubes, hoses and valves that conduct brake fluid through the system.

Drum Brakes

Drum Brakes are comprised of a drum & backing plate, a hub or axle assembly, brake shoes , wheel cylinder, wheel bearings and hardware necessary to mount these components on the vehicle. The wheel cylinder is connected to the master cylinder through tubes, hoses and valves that conduct brake fluid through the system.

Brake Fluid:

Brake fluid is a type of hydraulic fluid used in brake applications for automobiles and light trucks. It is used to transfer force under pressure from where it is created through hydraulic lines to the braking mechanism near the wheels. Braking applications produce a lot of heat so brake fluid must have a high boiling point to remain effective and must not freeze under operating conditions. Brake fluid is also designed to protect against corrosion of the system materials it contacts, however those corrosion inhibitors deplete over time.

Excessive moisture is also an issue. MAP continues to seek additional information from brake fluid manufacturers and other technical experts to identify the point of vaporization that may seriously affect braking efficiency and safety.

Things to watch for

*Scraping or grinding noise coming from the brakes

*Test of Brake fluid indicates a copper content of 200 ppm or greater indicating the need for a fluid replacement

*Brake pedal feels soft or spongy when the brakes pedal is depressed

*Vehicle pulls to one side when the brakes are applied

*Brake fluid level in master cylinder low

*Brake system Warning Lamp stays illuminated

Getting to know the truth about auto braking system

by

Tags: