Did you know that up to a third of the heat energy produced by an internal combustion engine ends up as waste heat in the cooling system? A gallon of gasoline produces about 19,000 to 20,000 BTUs of heat energy when it is burned, which is enough to boil over 120 gallons of water! So the two or so gallons of coolant that circulate within the typical automotive cooling system have to carry away a lot of heat. The radiator also has to be fairly efficient at getting rid of the heat, too, otherwise the BTUs will start to back up and make the engine overheat.

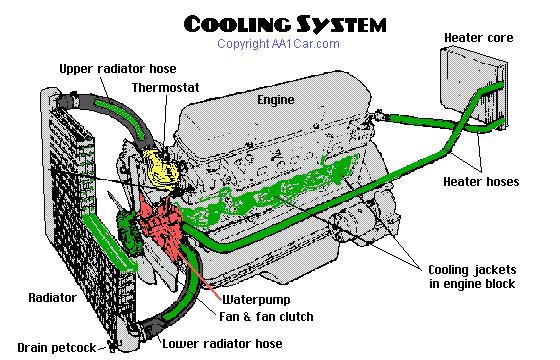

An efficient cooling system, therefore, requires several things: an adequate supply of coolant, an efficient heat exchanger, a fan to pull air through the radiator at low speeds, a water pump to keep the coolant moving, and a thermostat to regulate the operating temperature of the engine for good performance, fuel economy and emissions. The coolant must also have the right mix of water and antifreeze to provide adequate freezing and boiling protection, and the proper amount of corrosion inhibitors to protect against rust, oxidation and electrolysis.

To keep the cooling system in good operating condition, it is important to check the level, strength and condition of the coolant on a regular basis – and to replace or recycle the coolant before the protective additives are entirely depleted.

According to the U.S. Department of Transportation, cooling system failure is the leading cause of mechanical breakdowns on the highway. And according to numerous aftermarket surveys that have been performed over the years, coolant neglect is one of the leading causes of cooling system breakdowns.

Check the Level

One reason for checking the coolant level regularly is to detect leaks that can lead to overheating. The level should be checked at the coolant reservoir, not the radiator, because the radiator will siphon coolant from the reservoir when it is needed.

Most vehicles will lose a little coolant over time due to evaporation from the reservoir. But a significant loss of coolant in a relatively short period of time usually signals a leak, a radiator cap that is not holding pressure or a cooling system that is running too hot. Visually inspect the radiator, water pump, hoses, freeze plugs, etc. for external leaks, and then pressure test the radiator and cap to find out where the coolant is going. A tight system should hold the maximum rated pressure for at least two minutes with no drop in the gauge reading.

If you do not see any visible leaks and the system holds pressure, make sure the cap is good and has the correct pressure rating for the application (somebody may have replaced it with the wrong cap). Still cannot find where the coolant is going? Check the automatic transmission dipstick. A leaky ATF oil cooler loop in the radiator may be allowing ATF fluid and coolant to intermingle.

If the system does not hold pressure, you have found an internal leak. Now you have to figure out where. Check the level and appearance of the oil on the dipstick for coolant contamination in the crankcase. A higher-than-normal oil level and/or a foamy appearance to the oil or droplets of coolant on the dipstick would tell you the engine has a leaky head gasket or cracked block. Coolant leaking into a combustion chamber past the head gasket or through a crack in the cylinder head will often foul the spark plug and contaminate the oxygen sensor. The silicate corrosion inhibitors in conventional antifreeze will poison the O2 sensor, so plan on replacing the sensor(s) if this has happened.

If no leaks are found, the loss of coolant may be due to long-term neglect or a temporary episode of overheating. Has your engine overheated recently? A defective cooling fan, slipping drive belt, exhaust restriction (plugged converter) or even overloading the engine may have caused the system to get too hot and boil over.

Check The Strength

Checking the strength of the coolant to determine the concentration of antifreeze in the coolant is just as important for hot weather driving as it is for cold weather. A 50/50 mixture of ethylene glycol (EG) antifreeze and water will provide boiling protection up to about 255 degres F with a 15 psi cap, and freezing protection down to -34 degrees F. By comparison, a 50/50 mixture of propylene glycol (PG) antifreeze and water will provide boiling protection to 257 degrees F and freezing protection to -26 degrees F.

Increasing the concentration of antifreeze in the coolant will raise its boiling temperature and lower its freezing point. Even so, the maximum concentration of antifreeze should usually be limited to 65% to 70% because too much antifreeze and not enough water reduces the coolant’s ability to carry heat – which increases the risk of overheating in hot weather.

radiator corrosion

Something else to keep in mind is that EG and PG antifreezes have slightly different specific gravities (densities), so be sure you use the correct type of hydrometer, refractometer or test strip when checking the coolant.

Check The Condition

You cannot judge the condition of the coolant by appearances alone. It may look like new, but if the chemistry is not right the coolant can be a potential time bomb just waiting to cause problems.

Most antifreeze is about 95% ethylene glycol by weight, with the remainder being corrosion inhibitors and other additives. Time and heat eventually deplete the protective additives, leaving the system vulnerable to internal corrosion. Ethylene glycol never wears out, but the additives do so that is why the coolant needs to be changed or recycled after so many miles. Keeping the coolant up to snuff is especially important for vehicles with bimetal engines (iron block and aluminum heads) and those with aluminum radiators because aluminum corrodes more quickly than iron when the coolant chemistry turns sour.

The old rule of changing the coolant every two years or 30,000 miles is still valid for “conventional” green and yellow coolants. But the same also applies to systems filled with long-life coolant that may have been contaminated with conventional coolant. If long-life and conventional antifreeze are intermixed, the interaction between the additive packages can reduce the life of the long-life antifreeze from five years/150,000 miles down to that of ordinary antifreeze.

Unfortunately, it is difficult to tell if a system filled with long-life antifreeze has been topped off or intermixed with ordinary antifreeze. Dex-Cool in General Motors vehicles is dyed orange to distinguish it from ordinary coolant, but it takes a lot of green or yellow coolant to produce a noticeable change in color. If in doubt, it is always safer to err on the side of caution and go with the shorter service interval.

The best way to check the condition of antifreeze is with a chemical test strip that shows how much reserve alkalinity (which prevents corrosion) is left in the coolant. The test strip changes color when dipped in the coolant, allowing you to compare the color against a reference chart to determine the coolants condition. If the coolant tests bad or is close to borderline, replace or recycle it.

Rejuvenating The Coolant

There are three ways to rejuvenate coolant:

1. Recycle It. Take your vehicle to a shop that offers a coolant recycling service. Recycling machines can filter, clean and restore your old coolant to like-new condition. One of the main advantages of recycling is that it reduces hazardous waste disposal problems by concentrating harmful pollutants.

2. Treat It. Chemical additives are available that claim to restore corrosion protection without having to change the antifreeze. But, as any coolant chemist will tell you, such additives are a shotgun approach that may or may not achieve the desired results.

One additive you can use for preventive maintenance is a cooling system sealer. It should be the type that “melts” and circulates with the hot coolant. Bars Leak is a god choice here. As long as the sealer remains in the system, it will plug any small leaks that might develop (like pinholes in a heater core or seepage in a head gasket). Sealers can also prevent porosity leaks in aluminum heads, intake manifolds and blocks. That is why many engine rebuilders place a few cubes of sealer inside their engines. They know from experience that it reduces the risk of a comeback by preventing coolant leaks throughout the cooling system.

3. Flush & Replace It. Flushing is a must when draining and refilling the cooling system because flushing removes most of the old coolant from the engine block. It also helps dislodge accumulated deposits that can plug heater cores, radiators and interfere with proper heat transfer. Just draining the radiator can leave 30-50% of the old coolant inside the engine.

If the coolant contains sediment or there is evidence of scale buildup in the radiator or engine, a chemical cleaner should be used to remove the unwanted deposits.

Radiators

Maintaining the coolant will go a long ways toward prolonging the life of the radiator and other components in the cooling system. But if the coolant is not maintained, corrosion will eventually take over and attack the innards of the system. The most vulnerable components are the radiator and heater core, especially lead-soldered copper/brass heat exchangers in older vehicles. But aluminum radiators and heater cores are vulnerable to attack, too.

Lack of maintenance can also allow a buildup of rust and scale that can clog a radiator or heater core. Heat exchangers with extremely small passageways are especially susceptible to this kind of problem. Once clogged, heat exchangers are difficult to clean and replacement is usually necessary.

The average service life of an OEM copper/brass radiator is six to 10 years, and eight to 12 for aluminum. But even with good care, radiators can fail for a variety of reasons including vibration, mechanical stress and physical damage. Fatigue cracks can occur where the inlet and outlet fittings connect to end tanks, along tank/tube header connections, or where the radiator support brackets attach to the radiator.

Excessive heat can kill a radiator, too. Ones with plastic end tanks can be damaged by steam erosion if the coolant level becomes low and the engine overheats. White deposits on the inside of the plastic tank would indicate steam damage.

Replacement radiators are available in various styles and materials. What is important here is making sure the replacement radiator cools as well (or better) than the original. Compare the BTU ratings to make sure the replacement can handle the heat. Some “value priced” replacement radiators cut corners to reduce cost, and may not cool as well as the original. For normal driving, this might not be a problem but under heavy load or during unusually hot weather it might increase the risk of overheating.

When it comes to cooling capacity, it may be a good idea to upgrade – especially if a vehicle spends a lot of time idling in traffic during hot weather, pulls a trailer or is driven off-road. Aftermarket “heavy-duty” or performance radiators typically have additional rows of tubes, increased thickness and/or a more efficient fin and tube design to improve cooling performance.

For some applications, you may also have a choice between an aluminum or copper/brass replacement radiator or heater core. Aluminum is the most common material for newer applications (almost 90% of all new vehicles), while copper/brass is the most common material for older cars and trucks. Copper/brass was used almost exclusively up until 1980s when aluminum’s weight-saving and environmental advantages (no lead solder) brought it to the forefront. Some say copper/brass cools better than aluminum, but cooling efficiency depends more on the design of the radiator than the materials in it. The safest approach is to use the same type of heat exchanger as the original.

When a radiator is replaced, compare the width, height and thickness to see if any modifications will be needed to make it fit (hopefully, none will be needed). Aftermarket radiators may not always be an exact match with the original because of consolidation (especially if a copper/brass radiator is being replaced with one made of aluminum or vice versa). But as long as the size and location of the hose connections are the same or similar, it should create no installation problems.

On some newer vehicles, the radiator is part of a “cooling module” that includes the A/C condenser and fan. Some of these can be difficult to remove and may have to come out from the bottom rather than the top. Separating the radiator from the other components may also be a chore. And if it is a really new vehicle, the radiator may not yet be available as a separate item, which means you have to replace the entire module at added expense.

Other cooling system items that may also need to be replaced when changing a radiator include the upper and lower radiator hoses, heater hoses, hose clamps, water pump, fan clutch (on older vehicles with pump driven fans) and drive belts.

The old radiator cap should not be reused unless it has passed a pressure test. In fact, most radiator manufacturers say a new cap should always be used if the radiator is replaced. The new cap must have the same pressure rating as the original.

If the engine overheated, the thermostat also should be replaced as a precaution to eliminate the risk of a repeat boil over. Overheating frequently damages the wax element inside the thermostat. You also should check the coolant sensor to make sure it has not been damaged. Inspect the thermostat housing and replace it if it is badly corroded, warped or cracked.

When you refill the system, use a 50/50 mixture of antifreeze and distilled or deionized water. Hard water that contains dissolved minerals will shorten the life of the additive package in the antifreeze. Softened water should also be avoided because it contains salt (sodium chloride) that increases the risk of electrolytic corrosion.

Finally, the hardest part of replacing a radiator (or any other component in a cooling system) is getting all the air out when the system is refilled with coolant. Some vehicles have bleeder screws to vent trapped air. For those that do not, you may have to loosen and burp a heater hose to release trapped air.

Service Tip: If an engine overheats after you have refilled the cooling system, there may be some air trapped under the thermostat. An old mechanic’s trick is to take a small drill bit (3/32 inch) and drill a vent hole in the thermostat flange before the thermostat is installed. This will allow trapped air to pass by the thermostat. Some replacement thermostats already have this feature, and are called “jiggle pin” thermostats because the vent hole has a small pin in it to seal pressure but also vent air.

Servicing Your Engine’s Cooling System

by

Tags:

Leave a Reply